|

This project is part of the DFG priority programm "Elementary Processes of Organic Photovoltaics

Homepage of the TRAPOS research group: www.trapos.eu |

Project descriptionOrganic polymer solar cells (PSCs) offer a promising alternative to their inorganic counterparts due to their potential for low cost and light weight photovoltaic devices. Their development is connected to the rapid advances in the field of organic light emitting diodes (OLEDs). Semiconducting polymers exhibit electrical and optical properties similar to inorganic semiconductors while having attractive mechanical properties and processing advantages. In contrast to inorganic solar cells PSCs are considered for processing with established coating methods, e.g., knife coating, gravure coating and slot die coating for roll-to-roll production. |

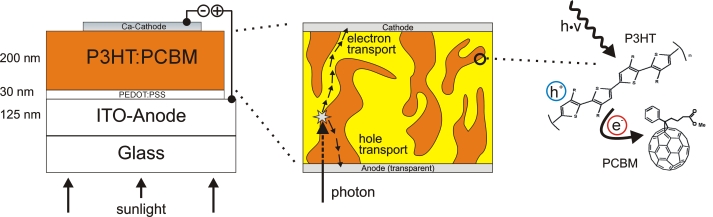

Figure 1: Layer structure of the polymer solar cell with approximate film thicknesses. Electron donor (P3HT) and acceptor (PCBM) are blended together to maximize the interface where exciton dissociation into electrons and holes takes place. For an effcient photocurrent, each material must provide a continuous path for electron and hole transport to the respective contact. Isolated domains can collect charges and cause recombination. Figure 1: Layer structure of the polymer solar cell with approximate film thicknesses. Electron donor (P3HT) and acceptor (PCBM) are blended together to maximize the interface where exciton dissociation into electrons and holes takes place. For an effcient photocurrent, each material must provide a continuous path for electron and hole transport to the respective contact. Isolated domains can collect charges and cause recombination. |

| The upscaling of these processes is a big challenge, since typical cell thicknesses are in the order of a few hundred nanometer. The structure and nano morphology of the photoactive blend is crucial for solar cell performance and depends strongly on drying kinetics and solvent properties. This project focuses on the drying characteristics of organic semiconducting materials and the influence of drying kinetics on the morphology. This will afford controling the structure formation due to the solvent recipe and adjusted drying kinetics. |